EXCLUSIVITY, QUALITY, INNOVATION

The 4tex Ltd company is practically the only domestic producer of carbon composites that is capable of manufacturing products precisely according to your requirements. That is possible thanks to our unique machinery and long-term experience in this field. Thanks to implementing the method of triaxial braiding of carbon fibres, our products are characterized by maximal hardness and strength accompanied by minimum weight. Currently we are able to manufacture products of the length of 5 meters and more.

Unlike our competitors, we are the true manufactures, not only dealers. When manufacturing the product, we use 95 % of biaxial and 100 % of triaxial carbon fibre braided sleeves of our own production. That is the only way how to guarantee the required quality and characteristics of the product. The individual layers are extremely important for the function of the composite product. They may be composed of carbon, glass, basalt, Kevlar or other combinations. The remaining 5 % of biaxial carbon fibre braided sleeves are bought, mainly because of the visual aspect.

HISTORY

Although the 4tex Ltd. Company was launched only in 2011, the founders’ experience goes far beyond that – before the year 2000. 4tex is a relatively young, completely Czech-owned company on the territory of the village of Uhřice. In a production hall of 500 m² various predominantly carbon-composite products are manufactured.

PRESENT STATE

Industrial production

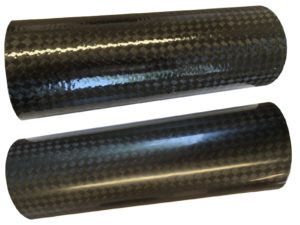

At present the company focuses on production made to order or in small series of carbon or glass-carbon cylinders and shafts. These products are used in industries mainly as winding mandrels, printing or even pressure cylinders. It is high strength, low weight and precision of performance that are the most demanded characteristics of these components. All these requirements reflect the fact that these cylinders are exposed to high speeds and pressures. To reach the desired quality, our company uses the modern methods of triaxial braiding combined with the method of classic winding.

To reach perfect axial symmetry of hollow profiles, our company offers post production machining, tailor-made to the customer’s wishes. After being further machined, the carbon cylinders achieve 0.02 mm precision. Moreover, metal end parts, fittings and other parts can easily be supplied.

For the final customer

Our company is well aware of the potential of carbon (composites) in the world of sport, be it products for automobile sport or sport generally. Our products are used in the manufacturing of motor boats, boat and windsurfing masts and hockey sticks. They may also be used as functional or aesthetic elements in automobile industry.

As the demand for our products is growing, we are beginning to make use of various carbon and hybrid woven fabrics/prepregs, not only to add to the aesthetic quality of the products. These woven fabrics may be applied by hand to the cylinder, as well as into the mould, which are made in our production or in cooperation with contracted companies.